Today, products with 3D images are becoming more and more popular, and if you want to start your own business in this area, then you should choose the right 3D printer, the buyer must fully determine the three selection criteria set before him:

- Purposes and objects of future three-dimensional printing, for the office or for home, it will be used;

- Technical education of the user / performer working with this device;

- What price level will be considered when buying.

After a thorough analysis of your abilities and capabilities, you can start choosing a reliable 3D printer that will serve its owner for many years and will have high quality products at the output.

The main characteristics of a 3D printer are the minimum thickness of the output layer, the types of materials it uses, the design features of the 3D printing device - including the print head - as well as the specifics of setting the printing program and the resulting printable area.

The main characteristics of a 3D printer should be considered in more detail.

Minimum outgoing layer thickness

Direct characterization of the detailing features of the product. Most 3D printers work on FDM (Fused Deposition Modeling) technology.<объектов>the method of deposition of the molten thread), layer-by-layer increasing the resulting object. Thus, the number stated in this characteristic indicates the thickness of the layer. In fact, the smaller the thickness of one layer to be built up - especially when printing human faces and art products - the higher the practical and aesthetic value of the resulting object. To obtain a high quality product, a layer thickness of 50 to 200 microns is used. For comparison - the thickness of a sheet of paper is 100 microns - 0.1 mm

However, the 3D printer will not necessarily produce the required layer thickness. The fluctuation factors of this value are the movement of air inside the device itself; change in room temperature; the presence of gaps - backlashes - in the design of the printer, contributing to the appearance of microvibration inside the device, as well as poorly adjusted distance between the nozzle and the platform of the printed structure.

The speed of movement of the print head - extruder - and the supply of plastic also have a tangible effect on the quality of the resulting product. In practice, in some printers, these speeds are related: the slower the head moves and the slower the plastic is fed, the better the layer build-up will be; in other devices, both values are controlled independently of each other.

Thus, the ideal product quality must be achieved by selecting the optimal balance of calibration, layer thickness, temperature and printer print speed.

Types of materials

A 3D printer operating in FDM mode, in most cases, uses PLA plastic in its work. This material is the most undemanding, it cools quickly when blown, it is resistant to deformation, but at the same time it quickly decomposes - in just a few years - due to the fact that it has an organic composition.

This material is also the most common material for creating decorative items for business and home.

In the creation of mechanical parts, parts of physical supports, as well as production forms and casings for molding, it is necessary to use ABS plastic, a slow-cooling, but reliable, durable and wear-resistant material.

The modern market for materials for 3D printers is constantly being modified and expanded. Now the user has access to a whole list of known and new compounds such as nylon, rubber, PVA, PETT, Hips and many others.

Ideally, it is best to purchase a 3D printer that works with most of these types of materials.

Working with ABS plastic

Full three-dimensional printing with this type of plastic is possible only if the printer has the following characteristics:

- heating the working extruder to a minimum temperature of 60 degrees (ideally - 280 degrees);

- heating the platform to a minimum of 80 degrees Celsius (ideally 110 degrees);

- the presence of a closed case.

Only if these characteristics are present, guaranteed professional ABS-printing will be produced, regardless of the characteristics declared by the manufacturer.

More specifically, in the absence of a back cover for the printer, printing large and medium-sized products will be problematic. If it is nevertheless necessary to manufacture the product, the printer must be covered with something and the room must be fenced off from drafts. Even if the fill of the material is medium, printing an object measuring 10 cm by 10 cm will take about 4 hours, and minimal deformation at an early stage of printing will ruin the entire product.

In the absence of heating of the platform, the plastic loses its ability to attach. This problem can be solved relatively easily with a special adhesive.

ABS plastic melts at a temperature of 240 degrees, but the quality of the product will suffer. Now on the market there are low-melting ABS filaments for three-dimensional printing, which require lower temperatures, but contain polyethylene in their composition, which spreads an unpleasant odor when heated.

It should also be remembered that the 3D printer has a tight clamp in the structure of the extruder for tightening the filament, which can be either focused exclusively on one type of plastic, or be universal, adjustable depending on the type of material.

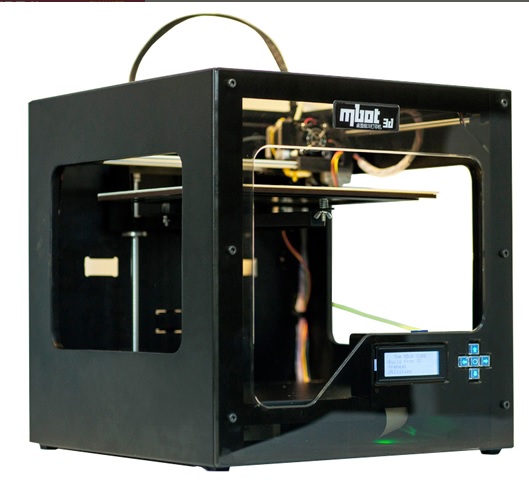

Design features of a 3D printer

It is impossible to choose the right 3D printer without knowing its design features. The extruder and platform are fixed and move along the axes and guides. The extruder is moved only strictly in the horizontal plane; the platform moves both horizontally and vertically - depending on the level of the current print. A 3D printer can have a different design, which does not affect the print quality at all. It depends on the material of the parts and the build quality. The rest of the printer is electronics, stepper motors, pulley and belts. The stability of the printer directly depends on the number of intermediary parts, as well as the gaps between them.

The structure of the print head

The principle of operation of the print head - extruder - is to squeeze out heated filaments of material with a thickness of 1.75 mm or 3 mm, which are in an almost liquid state, onto the surface of the platform. The extruder is necessarily programmed directly to feed the filament, and most often also to reverse (retraction). The extruder consists of several parts. On both sides of the thread there are two mini-wheels, one is an adjustable clamping wheel; the second is directly in front of the print head, with teeth, controlled by a stepper motor. The stepper motor feeds the filament into the extruder. Then the material goes through a mini-tube into the nozzle - and is removed by molten plastic. A temperature sensor and a heating element are connected to the tube. The clamping mechanisms as well as the different types of wheel teeth affect the type of plastic used. If a 3D printer has sharp and protruding wheels, then such a printer will perfectly produce products from Nylon and Flex (rubber).

Programmatic print setup

To create a three-dimensional artistic or industrial product, two types of programs are used - computer modeling and 3D printer control. Only programs of the second type make up a single set with the printer, and it is not possible to edit any properties of future products in them. They are equipped with simple functions for changing the rotation and dimensions of the product, but nothing more. In addition, by purchasing a printer with simple software control from the “print in one face” series, the buyer will inevitably receive a device with a somewhat narrowed range of possibilities. On the contrary, it will not be difficult for a confident PC user to master the skills of working in more complex 3D printing management programs. The quality of products created by such devices is beyond praise.

The files of almost all 3D printers are converted to STL format, which also processes product images using printer programs. On the Internet, there are thousands of options for sketches of future products for every taste and color, already recorded in the desired format.

In some 3D printers, almost all parameters are set automatically, in other printers, to achieve high-quality printing, you need to adjust the following values:

- head and platform temperature;

- head speed, plastic feed speed and first layer printing speed;

- layer, substrate and wall thicknesses;

- conditions for turning on the fan, its intensity;

- setting of supports, including their speed and intensity.

This is not a complete list of customizable printer characteristics for printing a future object.

Declared and Received Print Area

Plastic is prone to deformation. This tendency is especially intensified during long hours of printing. Therefore, it is necessary to immediately correctly and carefully configure the program in order to avoid further damage to the product. The workspace specified by the manufacturer will not necessarily be active in its entirety.

For example, an object with dimensions of 20 * 20 * 20 cm can be printed up to 15 hours, and 10 * 10/15 * 15 cm - about 4 hours.

Rating of the best 3D printers

If you want to buy a really high-quality item, then I advise you to go to, real specialists work there who will help you choose the right model that will suit you 100%. Well, in our turn, as usual, we will compile a rating of the best 3D printers for 2015-2016, which have become popular during this time.