A 3D printer is a device that allows you to produce various physical objects layer by layer, based on its 3D model. Despite the fact that such devices have recently become widespread, in fact, the first such devices began to appear back in the 80s of the last century. Of course, this was far from the best 3D printer, however, it already had interesting makings. In the process of development, she stepped far ahead, as a result of which a huge number of new devices appeared, each of which is distinguished by a mass of its advantages and features.

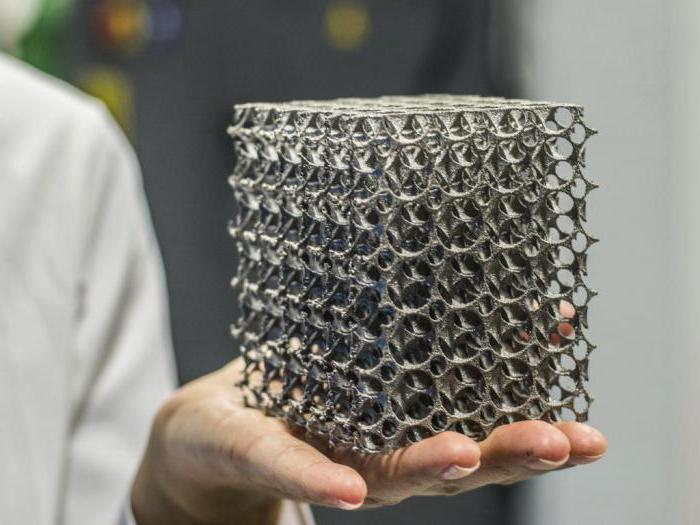

SLS (manufacturer sPro)

Laser selective sintering technology. Small particles of the material are sintered thanks to the action of a high power laser. In this case, powders of plastic, various metals, glass, nylon or ceramics can be used as a material. This structure is extremely accurate and does not require any supporting structures, but its implementation is quite expensive. Provides for the mandatory use of heat treatment of the product immediately after printing.

SLM (manufacturer sPro)

Laser selective melting technology. It is quite similar to the previous type of device, but here an extremely diverse powder metal can be used as a material, and the lasers themselves are even more powerful. This is the best 3D printer compared to the previous one for the reason that it does not require heat treatment of the finished product.

EBM (produced by Arcam)

Electron beam melting technology. Using a sufficiently powerful electron beam, the product is fused layer by layer of metal powder in a vacuum. Again, a better 3D printer than the SLS for the reason that it does not require post-print heat treatment.

LOM (manufacturer Solido, MCor)

The technology of layer-by-layer gluing of specialized film materials, such as laminated paper or polymer film, in order to subsequently form a full-fledged model with a laser beam.

SLA (Producer of FormLabs Form)

Another name for this technology is stereolithography. By curing the liquid photopolymer, which is under the influence of ultraviolet radiation on the desired areas, the formation of the article is ensured. The technology is quite accurate, but at the same time necessitates the use of supporting technologies. Among other things, one cannot but say that in this case expensive photopolymers are used, and the finished products differ in insignificant accuracy.

FDM (manufacturers: MarketBot, CubeX)

Modeling is carried out exclusively using fused technology. With the help of the dispensing head, drops of thermoplastic, which is in a heated state, are carefully squeezed onto the surface of the cooled platform. Due to the fast enough solidification and adhesion to each other, such drops form layers of the formed object, that is, here, too, printing is carried out in layers.

Reviews: We took one for ourselves for 20,000 rubles. In principle, they took it for fun, so he copes with his duties at 100. You download drawings on the Internet, program, wait, get the result - everything is simple.

Which to choose?

It is immediately worth noting the fact that household 3D printers are FDM, and only they are available for the average user. The point here is not even the peculiarities of this technology, but the fact that the device itself can be purchased at a price of 20,000 rubles, while the cost of other equipment starts from several million, and they themselves are supplied exclusively upon request.

That is why, if you are looking for consumer 3D printers, you must understand how to choose the most optimal device among the options with FDM technology.

What is it for you?

The main thing before buying this device is to decide what, in principle, you need this device for. For example, if you just want to have some fun, then a standard copy is quite suitable for you at a minimal cost. If you need to figure out which 3D printer is best for production or a certain business that is directly related to this printing, you should choose the most reliable model. One has only to imagine what could happen if during the process of printing the next order, the printer completely breaks down, and at the same time you cannot fix it in a short time.

Thus, if working on this device is for you direct earnings, then you should responsibly approach the choice of which of the 3D printers is better, of higher quality and more reliable, otherwise you better pay attention to the cheapest models in order to at least to understand how such equipment works.

Where are they made?

When choosing a printer, be sure to pay attention to the country of manufacture. Today the market is conditionally divided into three segments:

- west;

- Chinese;

- domestic.

Each of the above segments has its own characteristics, so it is impossible to immediately carry out, while reviewing, a comparison of the best 3D printers of each type.

Western models are imported to Russia and the CIS countries in small batches, while the manufacturers do not have any official representatives in our countries. In particular, this ultimately results in such problems as the rather high cost of equipment, lack of direct access to spare parts, as well as normal service and support. Thus, if even minor problems appear during the operation of your printer, there can be very serious problems in order to bring it back to working condition later. But a review of the best home 3D printers showed that in fact such devices are quite reliable and do not break in the course of their work.

Again, the same situation exists with Chinese printers, but in this case there is also an extremely low quality of this equipment. In particular, it is worth noting the quality of the main units and components, which is very far behind in comparison with the solutions offered by Western companies.

Of course, it cannot be said that only imported printers are relevant. It is very likely that you will be able to find the world's best 3D printers among our manufacturers. To do this, you can use the characteristics presented below.

Speed and precision

Accuracy provides for the height of the layer during printing, that is, the lower the height, the greater the accuracy (at the moment, the highest accuracy of printers is 50 microns), and the rotation speed is presented in cm 3 / hour.

These parameters interact with each other in the most direct way. If high accuracy is present, it decreases significantly and vice versa. For example, if a particular item is to be printed with the above precision of 50 µm, the build time will be approximately twice as long as it will take to manufacture that item with an accuracy of 125 µm. In the overwhelming majority of cases, manufacturers initially indicate what maximum accuracy and speed is provided for by their device.

You need to pay attention to the range of these characteristics in order for you to understand how diverse the models can be produced. For example, to print a large layout, you may need a fairly high speed, and at the same time a thick layer of application, while to print gears, you will already need to switch to a low speed in order to improve accuracy. It is worth noting that the ideal option for home is printers with an accuracy of 150 microns, which are not very suitable for printing various industrial objects or modern business.

Components and materials

When choosing the best 3D printer for your conditions, you should definitely pay attention to the conformity of all kinds of components and materials. It often happens that manufacturers claim extremely high printing accuracy (for comparison, each pixel in an iPhone is more than 50 microns), while the printer body is actually assembled from standard plywood, which does not allow for a rigid structure and corresponding accuracy. It is quite difficult to track these parameters via the Internet, except for certain photographs, as well as reviews of the devices themselves. The best option is to contact the seller directly and ask him all relevant questions.

Types of plastic

It is imperative to figure out which plastic for a 3D printer is better to use in this or that case. The most common in our time are PLA and ABS. A certain proportion of printers can use both types of such plastic, while other devices provide only one of them. However, in fact, in addition to the above, other variants of threads can also be used, which differ in very different physicochemical characteristics, such as glow in the dark, flexibility, solubility in water, increased strength, and many others.

The ability to print with a certain plastic is determined by the presence or absence of platform heating in the device, what the operating temperature range of the extruder is and what the design of the chamber for stamps is used. If you are not initially sure that the printer you have chosen provides support for a certain type of plastic, you need to clarify the specified parameters as much as possible, as well as compare them with those that are recommended for each specific plastic.

It is likely that some of the plastics options you may not need at all during the work, however, you will never know this in advance. For this reason, if you prefer to experiment or do not reliably know what devices and from what you will print, you should choose such a 3D printer, in which the maximum possible number of supported plastic filaments will be present. Even if such a versatile work of your device ultimately you will not need for your main work, who knows where else such a universal device can come in handy, because there are a variety of critical situations.